The pandemic fractured supply chains and recalibrated how consumers want to shop, pushing inventory management into the spotlight. Survivability became a question of agility. Many companies rose to the occasion by implementing new methods and breaking from the traditional supply chain focus on reliability, consistency, and low cost.

Now more than ever, it is critical for companies to reimagine their inventory placement strategies to meet the expectations of a consumer base that is increasingly shopping online. Executing the right supply chain strategy to drive sales and revenue is essential for gaining the greatest return on investment. Implementing the right inventory placement strategy is the key to getting there.

Smaller, closer, and faster

Supply chain leaders use product demand insights to improve inventory agility. For instance, companies are investing in mini-hub locations to hold faster-moving stock-keeping units (SKUs) closer to larger cities, where demand is high. This shift shrinks the lead time between the consumer and the product. According to the Future of Fulfillment Vision Study, about 78 percent of logistics companies expect to offer same-day delivery by 2023, and 40 percent anticipate delivery within a two-hour window by 2028.

E-commerce sales are also increasing. As detailed in one of our recent blogs, social distancing measures and other restrictions on brick-and-mortar store operations pushed buyers toward online channels. E-commerce sales reached 14 percent of total purchases in 2020 and are expected to soar to 20 percent of total retail sales in 2024. In response, retailers are boosting their physical store productivity by utilizing them as micro fulfillment centers. This strategy lowers overhead costs, enhances agility, and offers different pickup options for customers, all while expediting last-mile delivery.

Adding multiple inventory nodes makes inventory management significantly more complex. To minimize complexity, focus on four key strategies:

- Understand your service goals and lead-time expectations: A successful inventory optimization strategy begins with a clear picture of the customer's business and service-level expectations at the SKU or channel level. Additionally, examine where your competition stands with customer expectations so that you can narrow in on the service-level expectations. These expectations will provide a “true north” in developing an optimal inventory strategy to align with your customer and business objectives.

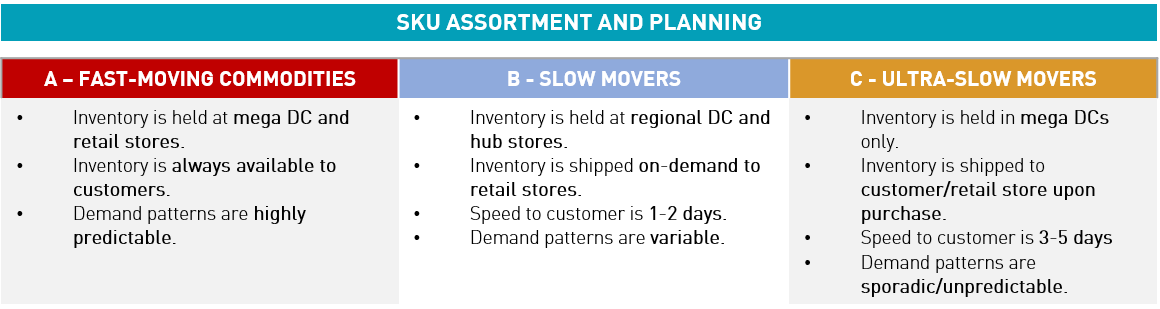

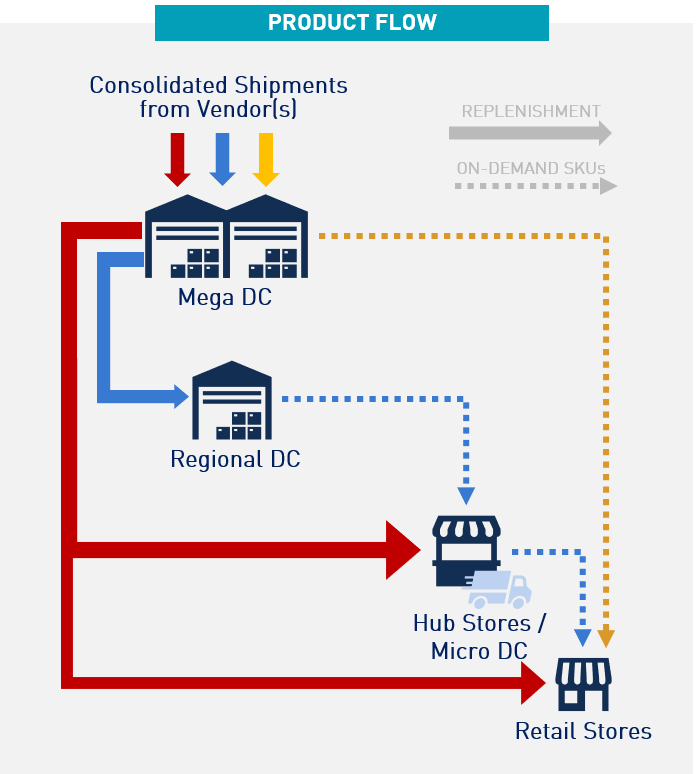

- Define your SKU strategy and demand planning rules: For example, consider using an ABC classification method by grouping inventory into tiers based on demand patterns, the speed at which inventory moves, and the speed at which the competition is fulfilling regionally. The goal should be to define supply chain flows, demand planning rules, replenishment frequencies, and safety stock sizes for your tier of SKUs. Carefully assess the complexities to confirm the organization can manage the demand planning rules. The “speed-to-customer” goal should not conform to a one-size-fits-all mold. Instead, think of it as a matrix that aligns inventory strategies based on market or geography and product type.

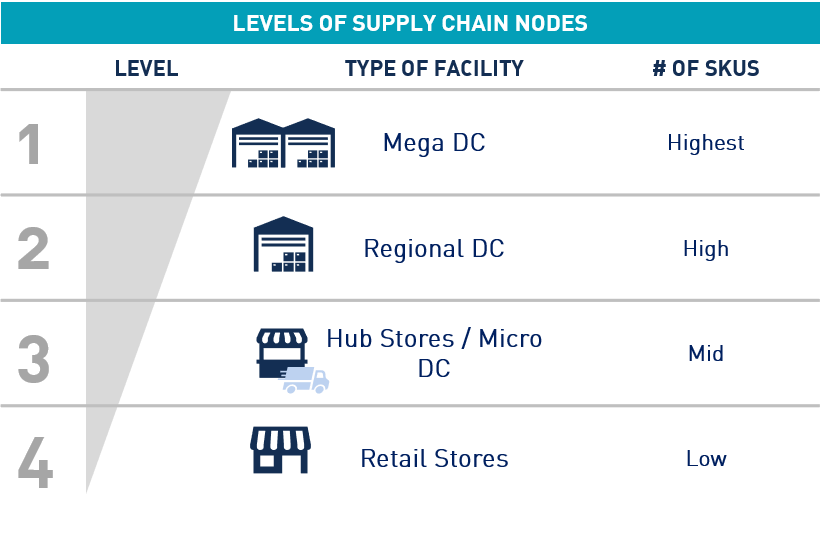

- Define the distribution network and inventory nodes: This can range from having two to four levels of facilities, including mega distribution centers (DCs), regional DCs, hub stores, and retail stores. As supply chain leaders look to increase inventory agility, we’ve seen a shift away from centralized DCs and toward regional and micro DCs.

- Optimize product flow: Review the flow of products from vendors to inventory storage nodes, minimizing extra handling and lead time. Ultimately, your enhancements here will drive inventory sizing and optimization, but the results will depend on how effectively you’ve deployed elements of the previous three focus areas.

The capabilities you need for a nimble supply chain

Several other macro trends have put additional pressure on supply chains. In this dynamic environment, executives are challenged to build increasingly flexible supply chains. Consider, for instance, the accelerated population migration from the Western and Northeastern U.S. to the Southern U.S. This shift will alter geographic demand patterns significantly in the next decade, necessitating a more flexible supply chain.

Developing an agile supply chain supported by inventory optimization will require three key capabilities:

Customer-centric demand forecasting:

- Shifting from a product-focused to a customer-centric approach will enable companies to combine customer behaviors and demand signals with core functions such as forecasting and planning to improve predictability.

- With many companies emphasizing speed-to-customer, multi-tiered networks will allow them to reach customers faster, but these networks will also be increasingly complex. As a result, we expect that localized demand planning will drive inventory management.

Data-driven network optimization:

- As market dynamics continue to shift, companies are reevaluating their network footprints to ensure that they can provide competitive service levels at an optimum cost.

- To ship faster and cheaper while maintaining the desired customer experience, focus on having the right inventory in the right locations at the right time. Companies should use a data-driven approach to design an optimal network with the right balance of DCs, micro-fulfillment hubs, and ship-from-store locations. Data can also help supply chain leaders define product flows to meet desired inventory goals.

Real-time, multi-channel inventory view:

- Multi-brand retailers tend to leverage multi-channel inventory management to sync products across channels (retail and DTC primarily). This approach also offers real-time visibility into a shared inventory, minimizing the risk of missed orders while maximizing order fulfillment efficiency.

- A gap between what is available in-store or online vs. what is showing in the inventory will result in additional fulfillment costs and increased delivery times.

Change is constant

Just as the business landscape is constantly in flux, your inventory optimization strategies and supply chain capabilities are also ever-changing. As a result, they require frequent synchronization with your overall business strategy. To succeed, it’s more important than ever that your supply chain organization and supporting functions remain agile. Reevaluate them frequently against business strategies, technology platforms, and demand flows to meet evolving customer expectations.